UL TPU Cable: A High-Performance Wiring Solution for Modern Technology

In an era where technology powers everything from smart homes to autonomous vehicles, the quality of internal components—like cables—plays a significant role in overall performance, safety, and reliability. While the spotlight often shines on processors, sensors, and software, the unsung heroes of tech infrastructure are the cables that connect and support these systems.

One such innovation in the cable world is the ul tpu cable a durable, flexible, and safety-certified cable solution that’s gaining traction in industries ranging from automation and robotics to medical devices and consumer electronics.

What is a UL TPU Cable?

To understand what makes a UL TPU cable so special, let’s break down the acronym:

- UL refers to Underwriters Laboratories, a globally recognized organization that certifies the safety and compliance of electrical components. A UL-listed cable meets strict standards for flame resistance, performance under stress, and long-term reliability.

- TPU stands for Thermoplastic Polyurethane, a high-performance plastic known for its flexibility, toughness, and resistance to abrasion, oils, and chemicals.

A UL TPU cable, therefore, is a wire or cable with a TPU outer jacket that has passed UL’s rigorous testing criteria. It offers high endurance in both mechanical and environmental aspects—making it a premium option in demanding applications.

Why TPU is the Preferred Jacketing Material

Traditional cables often use PVC or rubber as their outer material. While both materials have their merits, they fall short in challenging environments. TPU, on the other hand, provides:

- Superior abrasion resistance

- Excellent flexibility, even at low temperatures

- High resistance to oils, fuels, and chemicals

- UV and ozone resistance

- Low smoke and flame retardant properties

These traits make TPU the ideal material for a cable jacket, especially in environments where cables are exposed to movement, chemicals, or physical stress.

See also: Understanding Geogrid: Strength Beneath the Surface

Key Advantages of UL TPU Cables

1. Enhanced Safety Through UL Certification

UL certification is a mark of trust. It assures that the cable won’t fail under normal operating conditions and meets essential fire and electrical safety standards. For industries like medical equipment or industrial machinery—where lives and operations depend on safety—this certification is critical.

2. Durability in Harsh Environments

A UL TPU cable is designed to survive the harshest conditions. Whether exposed to oils in an automotive assembly line or chemicals in a laboratory, TPU resists deterioration. Its mechanical strength also means it won’t crack or wear easily in high-friction or vibration-heavy settings.

3. Flexibility for Motion-Based Applications

In robotics or CNC machines, cables are constantly in motion. TPU’s rubber-like flexibility ensures that UL TPU cables can bend, stretch, and move repeatedly without degrading—a key advantage over stiffer PVC alternatives.

4. Lightweight Yet Strong

Despite their durability, TPU cables are lightweight. This feature makes them particularly attractive for aerospace and consumer electronics applications, where weight can directly affect design or performance.

Industry Applications of UL TPU Cable

The unique properties of UL TPU cables make them suitable across a wide spectrum of industries:

✅ Industrial Automation and Robotics

In manufacturing settings where machines are in continuous operation, cables are subject to frequent movement and exposure to lubricants and coolants. UL TPU cables are perfect for such scenarios due to their durability and flexibility.

✅ Medical Equipment

Medical devices must meet high standards for hygiene, reliability, and mechanical performance. TPU is easy to clean, resistant to body fluids and disinfectants, and safe for patient-connected equipment.

✅ Telecommunications

In networking and data transmission systems, UL TPU cables provide strong shielding options and physical protection without adding excess weight or bulk.

✅ Automotive and Transportation

UL TPU cables are increasingly used in electric vehicles (EVs), where compact, chemical-resistant, and thermally stable cables are needed to handle charging systems, sensors, and battery management systems.

✅ Consumer Electronics

From phone chargers to gaming peripherals, TPU jacketing is valued for its smooth finish, resistance to fraying, and long-lasting performance—even under heavy use.

Comparing UL TPU Cable to Other Common Cable Types

| Feature | UL TPU Cable | PVC Cable | Rubber Cable |

| Flexibility | Excellent | Moderate | Good |

| Abrasion Resistance | High | Low | Moderate |

| Oil/Chemical Resistance | Excellent | Poor | Good |

| Environmental Durability | High | Low | Moderate |

| Weight | Light | Moderate | Heavy |

| Certification Available | UL Listed | Sometimes UL | Sometimes UL |

As the table shows, UL TPU cable generally outperforms both PVC and rubber in critical performance areas—especially in applications demanding both durability and safety.

Customization Options for UL TPU Cable

Many manufacturers offer custom versions of UL TPU cables to suit specific industry needs. These customizations include:

- Color coding for easier installation and identification

- Shielded variants for EMI protection

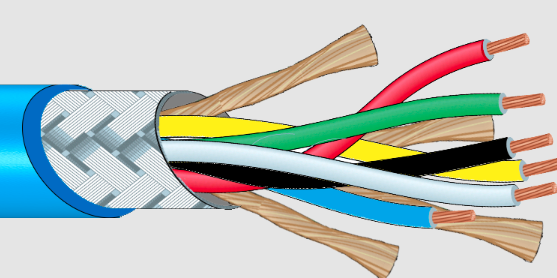

- Multi-core designs for compact power and data delivery

- Halogen-free compositions for use in enclosed environments

- Coiled cables for retractable or mobile device integration

This level of customization makes UL TPU cables highly versatile and adaptable to advanced technology applications.

Conclusion

In a high-tech world where safety, durability, and efficiency are paramount, UL TPU cables provide an exceptional wiring solution. Whether you’re an engineer designing the next robotic innovation or a manufacturer setting up a smart factory, this cable type delivers the robustness, flexibility, and peace of mind you need.

Combining the trusted certification of UL with the mechanical excellence of TPU, UL TPU cables are more than just wires—they are enablers of modern technology.