Decoding Crystalline Structures: The Critical Role of the X Ray Diffractometer in Modern Science

In the realm of material science, chemistry, geology, and nanotechnology, understanding a material’s internal structure is crucial. The arrangement of atoms within a crystal determines its physical and chemical properties. To unveil this hidden world, scientists rely on a powerful and precise instrument—the x ray diffractometer.

The x ray diffractometer (often abbreviated as XRD) has become a foundational tool in laboratories around the globe. Its ability to non-destructively analyze crystalline substances has propelled research and innovation across countless industries. This article dives deep into how an x ray diffractometer works, its components, applications, and why it’s indispensable in both academic and industrial settings.

What Is an X Ray Diffractometer?

An x ray diffractometer is an analytical instrument used to determine the crystallographic structure, chemical composition, and physical properties of materials. It operates on the principle of X-ray diffraction, a phenomenon where X-rays interact with the atomic planes in a crystal, resulting in a unique diffraction pattern.

This diffraction pattern serves as a “fingerprint” for the material. By analyzing the angles and intensities of the diffracted beams, scientists can deduce the crystal structure, lattice dimensions, and even identify unknown compounds.

Basic Principle of X-Ray Diffraction

X-ray diffraction is governed by Bragg’s Law:

nλ = 2d sin θ

Where:

- n is an integer (order of diffraction)

- λ is the wavelength of the incident X-ray beam

- d is the distance between atomic planes in the crystal

- θ is the angle of incidence

When a beam of monochromatic X-rays strikes a crystal, it gets diffracted in specific directions. By measuring these angles and intensities using the x ray diffractometer, one can calculate the spacing between planes in the atomic lattice and reconstruct the 3D structure of the crystal.

See also: Bi LED Lens Technology: The Future of Night Driving from the Best LED Headlight Brand

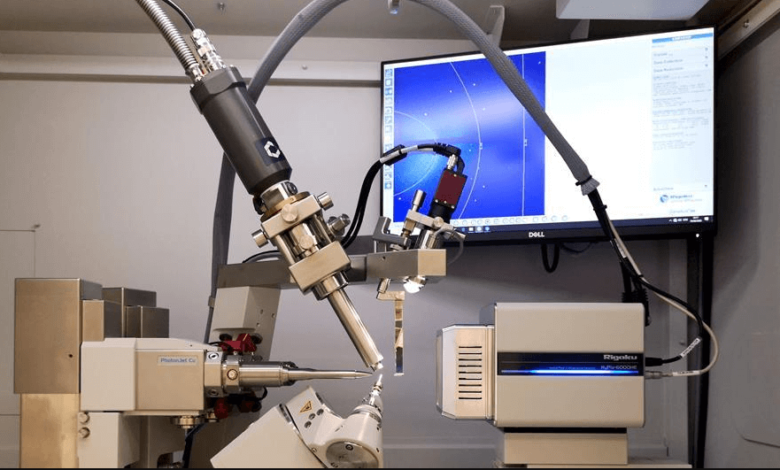

Key Components of an X Ray Diffractometer

Modern x ray diffractometer systems consist of the following main components:

✅ X-ray Source

Generates a focused beam of X-rays, typically using a sealed tube or rotating anode containing a target material (like copper or molybdenum).

✅ Goniometer

Holds the sample and allows precise rotation around one or more axes to achieve different angles of incidence and detection.

✅ Sample Holder/Stage

Where the powdered or solid sample is mounted. Some advanced systems offer temperature or atmosphere control.

✅ Detector

Captures the diffracted X-rays and converts them into electronic signals, allowing measurement of intensity versus angle (2θ).

✅ Data Processing System

Software that collects, processes, and interprets the data, enabling crystal structure refinement and comparison to standard databases.

Types of X Ray Diffractometers

Depending on the application, x ray diffractometer systems come in various configurations:

1. Powder XRD (PXRD)

Used for analyzing polycrystalline or powdered samples. It’s the most common type and ideal for identifying unknown materials.

2. Single Crystal XRD

Used for high-precision structural analysis of a single crystal. It provides highly detailed 3D atomic models.

3. High-Resolution XRD

Applied in thin-film and semiconductor analysis, this type offers extremely fine angular resolution.

4. In-situ XRD

Allows real-time measurement of structural changes under varying temperatures, pressures, or atmospheres.

Applications of the X Ray Diffractometer

The x ray diffractometer finds use in a wide array of scientific and industrial sectors:

🧪 Material Science

Identify phases in alloys, ceramics, and polymers. Analyze defects, stress, and grain size in engineered materials.

💊 Pharmaceuticals

Verify polymorphs in active pharmaceutical ingredients (APIs), ensuring proper drug formulation and stability.

🧬 Nanotechnology

Study nanocrystalline materials and thin films to determine crystallite size, texture, and lattice strain.

🪨 Geology and Mining

Identify minerals and ore compositions. Evaluate the crystal structure of rocks and sediments.

🏭 Cement and Construction

Monitor hydration phases in cement and diagnose potential failure mechanisms in concrete.

🧫 Environmental Science

Track contaminant phases in soils and sediments. Investigate heavy metal binding in waste materials.

Advantages of Using an X Ray Diffractometer

Why has the x ray diffractometer become a go-to tool across scientific disciplines? Let’s explore some of its key advantages:

✅ Non-Destructive Testing

Samples remain intact after testing, making it suitable for rare or valuable specimens.

✅ High Accuracy

Determines atomic-level structure with unparalleled precision.

✅ Rapid Identification

Many materials can be identified within minutes using existing databases.

✅ Versatile Sample Types

Handles powders, thin films, liquids, bulk solids, and even biological crystals.

✅ Rich Data Output

Beyond just identification, it offers insights into crystal quality, phase transitions, and defects.

Choosing the Right X Ray Diffractometer

When selecting an x ray diffractometer, consider the following factors:

- Sample Type: Powders, thin films, or single crystals?

- Resolution Needs: Do you require basic identification or detailed structural refinement?

- Speed vs. Detail: Faster instruments may compromise on resolution.

- Automation: Advanced labs may benefit from robotic sample changers or remote access.

- Software: Look for intuitive, database-integrated software with strong analytical capabilities.

- Budget: Entry-level benchtop models differ greatly from high-end synchrotron-compatible units.

Real-World Examples of XRD in Action

“In our R&D lab, we rely on the x ray diffractometer to confirm the crystal form of new drug candidates. Even small changes in structure can impact bioavailability.”

— Lead Scientist, Pharmaceutical Company

“We used XRD to identify unknown minerals in an archaeological dig. It helped us confirm the presence of rare volcanic materials.”

— Geologist, Academic Research Project

“Our materials team uses it daily to ensure that thin films deposited on semiconductors are correctly oriented. It’s a vital quality control tool.”

— Process Engineer, Semiconductor Industry

Conclusion

The X ray diffractometer is not just a laboratory instrument—it’s a window into the atomic world. With the ability to determine material identity, structure, and quality, it plays a pivotal role in discovery, development, and production across industries.

As materials grow more complex and innovation accelerates, the importance of structural analysis will only increase. Whether you’re uncovering ancient minerals, developing next-gen batteries, or formulating life-saving drugs, the x ray diffractometer will remain your most trusted companion in scientific investigation.